Many model train layout designers try to have the maximum spur lengths they can, to maximize how many cars can sit at the industry, and therefore maximize their train lengths. There’s nothing wrong with this but you should consider how the industry actually uses the spur.

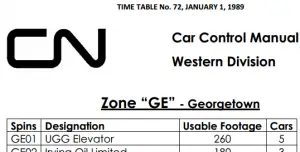

I’ll give an example: the grain elevator spur in Georgetown on my layout. The absolute maximum usable length of the track is 105 cm (41.3″) without cars blocking the main line. In HO scale terms that’s 91.35m / 300′, and it’s listed in the CN timetable as 260′ of usable footage (see above).

Given that a grain car is 50′ long (without couplers) in real life, that should translate to 5 cars capacity, and it is indeed listed in the timetable that way.

Here’s how the spur looks with 5 cars in it. They fit comfortably.

So what’s the problem?

The problem is that there is no place to move cars within the siding. Here’s how the grain elevator would actually use the cars:

- CN pulls whatever cars are in the siding.

- CN delivers empty cars to the elevator, spotting one of them beside the elevator.

- The customer fills the spotted car with grain.

- Using a car puller, gravity, or some other means, the loaded car would be rolled away and the next empty car would be spotted at the elevator.

- Repeat steps 3-4 until all cars are filled.

- The customer contacts CN for a pickup, and perhaps requests more empties at the same time.

Steps 4-5 are why you can’t fill the siding with cars – you need a place to put the loaded cars!

I will be operating this layout with a maximum of 3 cars. That gives 2 cars of space to roll the loads into with the third load spotted at the elevator.

Think of other industries and how they would use their spurs. Can cars only be loaded or unloaded at particular locations on their spurs? Other industries that come to my mind include oil spurs and paper mills.

Have a look at Chris Mears’ post on loading 100 cars in 15 hours to see how one elevator does it. You’ll see how they need empty spots too!

Happy operating!