My niece and nephew were over for a visit a few days ago, and my nephew wanted to see the “choo choos”. We went downstairs and he got up on the step stool to see the trains. He showed me that he wanted an intermodal train to run, so I hitched CN 3665 to the head end and pulled a train of six or seven well cars out of Brandon around the layout. As we often do, I also started a CP train going around the CP tracks with 4505 in the lead.

Suddenly, the layout ground to a halt. The CN train had stopped on the east siding switch in Georgetown.

My NCE Power Cab controller was constantly resetting, indicating a short somewhere.

I immediately blamed 3665 in my head, as it has been known to short out Peco switches. It did seem strange to me that it was doing this, as it has gone through that switch literally dozens of times without incident.

I pushed the train a bit and the short was cleared, so I restarted operations. The next time 3665 and the train came around to that spot, it happened again. And again.

With my nephew there, I didn’t have time to get into debugging the situation, so I decided to do something different with 3665 and we went to switch Helene a bit. After that, he lost interest so I shut everything down.

Later, I had some time to debug the problem. I drove the train around to the same spot and the short happened again. At least it was reliable!

I lifted 3665 off the rails, and the short did not clear. Oh! It wasn’t 3665 after all…

I lifted each of the following freight cars off until I found the culprit, a DTTX well car. I think it’s a Walthers model but it’s not shown on the car. This car has a metal body and metal wheels, so I figured the wheels must be contacting the body on both sides and that’s where the short is happening. A little “wheel rub” as it were.

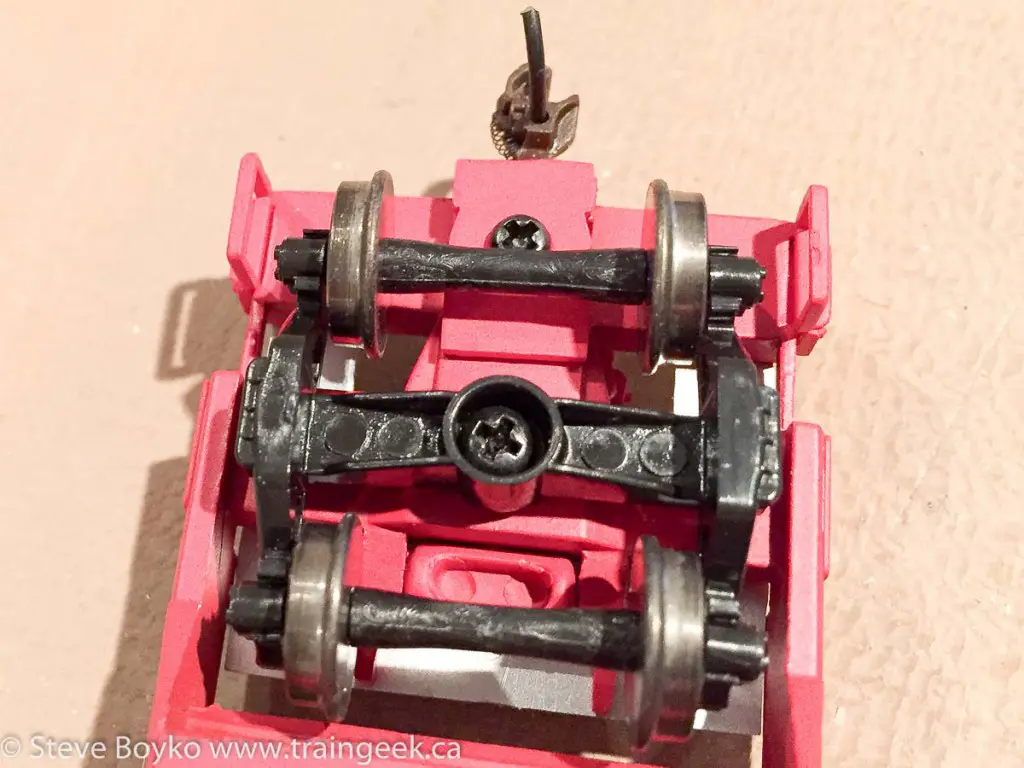

You can see there is not a lot of clearance between the wheels and the body.

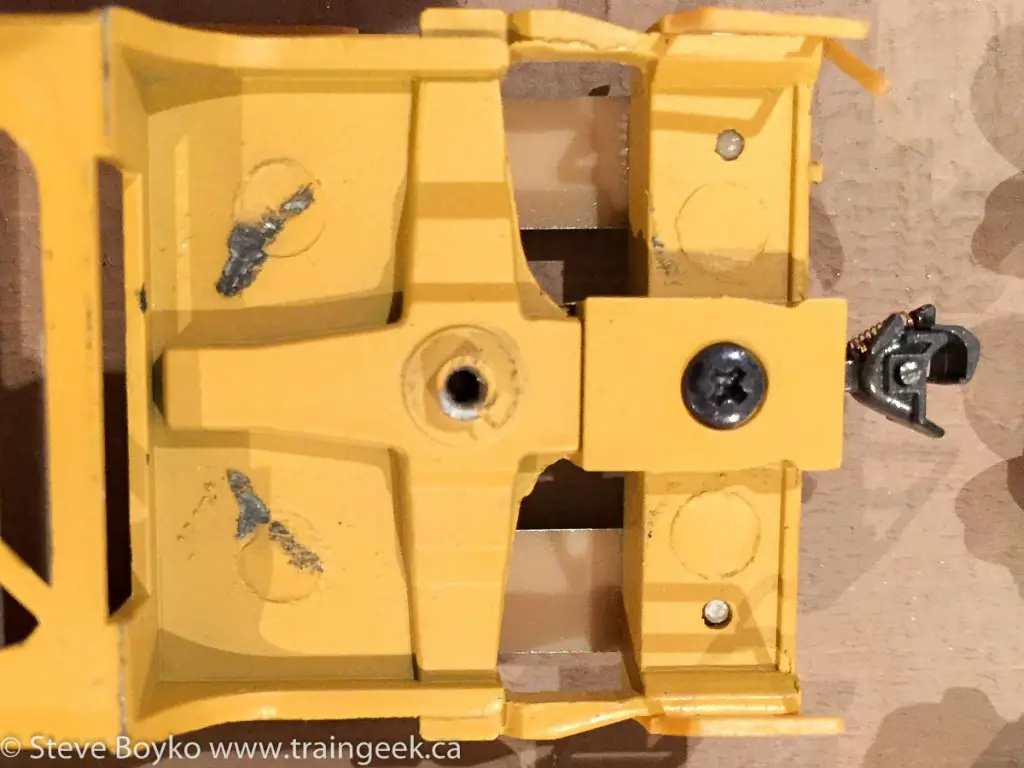

This car is a bit banged up!

I took it off the rails and turned it over, then removed the trucks. The problem was immediately obvious.

The wheels were rubbing against the frame and had worn through the paint to touch the bare metal of the frame itself.

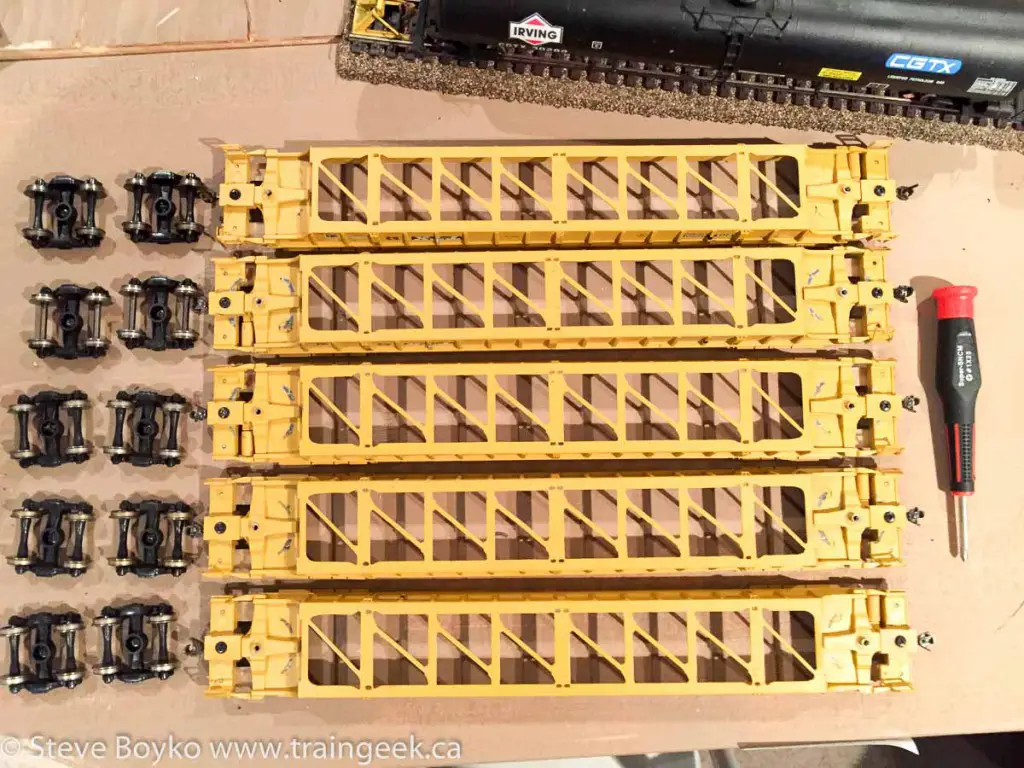

I pulled all of my intermodal cars out of service and examined them. It turns out that I have five cars that have the same problem. Click on the photo to see a larger version.

My other intermodal cars don’t have this problem, because they either have plastic wheels, plastic bodies, or there is no metal above the wheels, like this BNSF car.

So… what’s the solution?

I decided to paint over the scratches with a thick layer of paint, and also to insert a wheel washer between the truck and the body to give a tiny bit of space. I don’t want to raise the car too much because there would be coupler alignment issues.

It’s not an ideal solution but it’ll do for now. Any suggestions?