Prototype: Loading Ramp at Debert

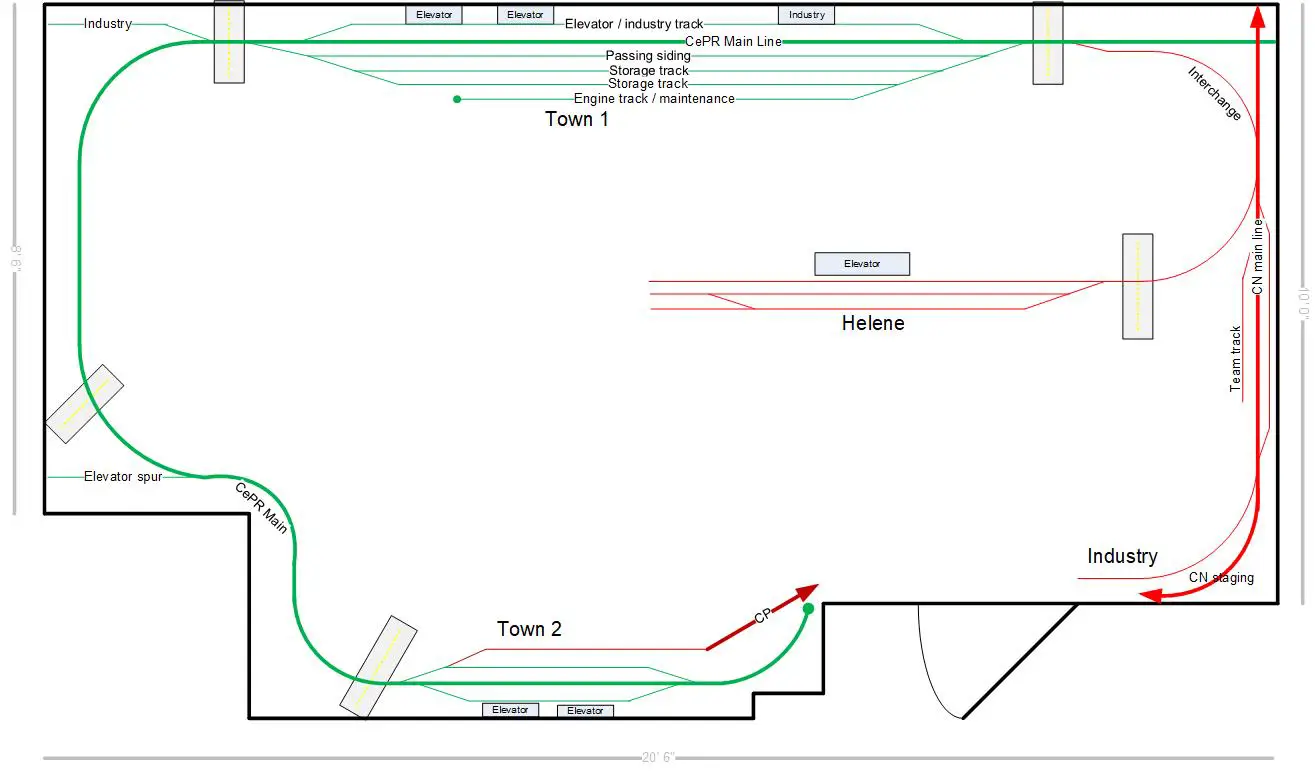

I recently constructed a loading ramp on my layout to better serve the CN team track. It was loosely modeled after a few ramps I’ve seen in the past, including the loading ramp that used to be in Debert, Nova Scotia.